1D. Closed garage with combined detection

Dimmable fittings with ‘Dynamic Lighting control’ HF operating devices

Svenskt patent nr. 9201493-5, English patent No. 0659329

| Premises

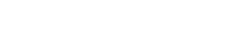

For a closed single-level garage, acoustic technology is unsurpassed it is the only technology that permits activation before entry into the premises. In this example detection is supplemented with an IR detector that covers the laundry area and part of the garage. The lighting is also activated by a magnetic contact in the inner door in the passage to the stairwell and by the code lock when driving in. For multi-storey open garages we refer to detection using IR detectors. Light sources This application shows an example of fittings with dimmable HF operating devices. Positioning of detectors The microphones should be positioned at up to twice the radius between them. The range of the microphones can be 20 – 25 m radius depending on acoustic conditions. Ceilings provided with acoustic plates can reduce the range of the HF signal. Connection of the microphones, which are connected in parallel, can use EKKX 1 x 4 x 0.25 mm2. The IR detector is positioned at 45° to the wall and helps cover the laundry area, where relatively quiet work sometimes occurs. It simultaneously covers the whole of the inside of the garage. The garage doors are rolling, which means they do not produce any infrasound when they open. The code lock is thus connected to the AD-600 acoustic detector to ensure activation upon entry. |

Control system

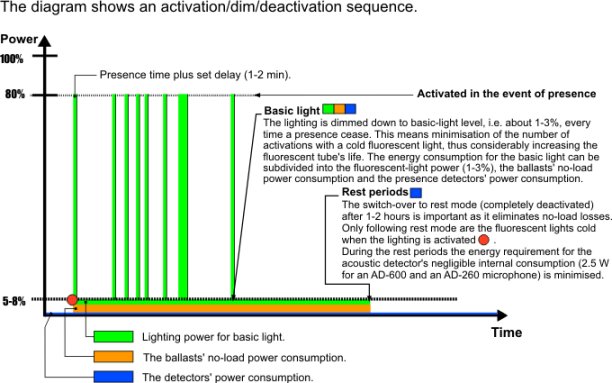

I garages there is a risk of many activations with the consequent increased wear on light sources and operating devices if you do not do things correctly. With new buildings or renovation where you have the option of selecting operating devices in the fittings, based on experience and the state of technology, it is now a serious error not to implement an installation in accordance with the ‘Dynamic Lighting Control’ principle. Upon entry into the garage the lighting is activated at the normal level set on the ‘High’ potentiometer in the level selector NV-2, e.g. approx. 80 per cent. The lighting remains on at 80 per cent throughout the period of presence. When the presence ceases + following the delay set for relay output A, lighting drops to basic light level. It is set to about 2 per cent on the ‘Low’ potentiometer in NV-2 and it does not get completely dark in the garage. A photoelectric cell can be connected to the acoustic detector, and it will block detection when natural light suffices. If there is no presence in the garage for an extended period, e.g. 60 min. set as the delay for relay output B, the lighting is completely switched off for a rest period, to avoid no-load losses. The maximum delay that can be set for relay output B is 200 minutes. Shown here is a wiring diagram for Dynamic Lighting Control using acoustic detection. NB: The acoustic detector only works in a closed garage. NV-2T level selector is also available with DSI control (NV-2TDSI). See application 1F with four lighting levels and daylight-dependent control. With knowledge of current technology, it is bad practice not to utilise Dynamic Control in frequently used premises. |

||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

Information for current budget

|

|

||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||